Complete software for every visualization and monitoring need

With Premium HMI software platform, ASEM has been providing valuable visualization systems appreciated for the quantity and quality of the functionalities available and the transversality of the platform, which makes it possible to use the same project both on HMI solutions based on ARM or x86 hardware platforms (also with multicore architecture support), with WinCE or WIN 32/64 Runtimes without any need to modify or change settings in the ‘Premium HMI Studio’ development tool.

Premium HMI 5

PHMI 5 supports the latest Microsoft® XAML visualization technologies that enable the design of advanced and modernoperator interfaces, typical of latest generation mobile devices.

PHMI 5 supports 16 million colours, manages transparency and colour shade effects, supports multitouch gestures which further improve the user experience of HMI projects and provides a rich library of graphic objects particularly accurate from an aesthetic and ergonomic point of view making it possible to design unprecedented user interface screens.

The XAML graphic objects library, available for Win CE and Win 32/64, is added to the existing library maintaining full compatibility, so that the user just needs to make a mouse click in the development tool to convert existing projects introducing new graphic objects without making any changes, retaining all scripts assigned to graphic objects or variables linked to properties that vary dynamically. PHMI 5 is a unique HMI platform in the competitive context due to the possibility to develop the graphical interface with XAML objects and Windows CE enviroment.

Multitouch and OPC UA

Premium HMI 5 supports Multitouch programming for Win 32/64 and WEC 7 systems with multicore processors and supports OPC UA protocol, leading the way to the distributed connectivity of the "Industry 4.0" and Industrial "IoT".

"Total Cost of Ownership" reduction

With the intuitiveness of Premium HMI object design, the project debugging tools and the possibility to use a single development tool for any type of application (from the simplest on operator panels to the most complex on Panel PCs or the most innovative on smart mobile devices), it becomes easy to save a considerable amount of time in learning, personnel training, application maintenance and end-user support and service.

Features

Premium HMI Studio

A unique development tool to realize HMI projects for Windows CE and Windows 32/64 operating systems on ARM and x86 hardware platforms

• Object-oriented programming to drastically reduce use of code in project development, thus saving time not only in designing but also in project debugging and maintenance

• Ergonomic and highly configurable development tool (floating and traditional windows, shortcuts and configuration pop-ups) to fully adapt to every kind of requirement

• Wizard for project quick development (templates, automatic creation of project pages, title headings, navigation keys, alarm model and Data Logger model)

• Project explorer with hierarchical tree view of resources (selection of multiple objects and single components of a group, copy/paste function support)

• Support of layer programming with layer visibility management (configured objects of the various synoptics can be attributed to different layers)

• Support to automation system modeling by means of compex data structures, also including substructures, and ability to import them from CODESYS

• Distributed project planning with support of "Father project / Child project" philosophy which dynamically links and integrates decentralised projects (the Father project includes all the resources of the Child project as if they were its own)

• Export and import of variables, languages and translations, alarms and logs in .CSV format

• Wide graphic symbols library (also with integrated animation logic), organised in categories with immediate display of preview and Drag&Drop in synoptics. Possibility to create new symbols and new categories

Latest generation graphic user interface

Premium HMI offers the most advanced graphic technologies based on XAML standards and it is the only visualization solution supporting XAML vector graphics also on Windows CE operating system.

• Premium HMI introduces a new 16 million colours graphic rendering engine supporting XAML advanced graphic technologies

• Sophisticated management of transparency and shading effects

• Automatic re-Dimensioning of screens for devices with different graphic resolutions; this feature of Premium HMI allows existing projects to be easily reused on different systems regardless of the graphic resolution of the display

• Rich gallery of vector graphic objects (buttons, switches, analogue displays, sliders, etc.) to realise unprecedented user interface projects

• Complete set of graphic animations (including movement of objects along definable routes)

• SVG import functionality

• «Alias» support and inheritance of symbols with definition of public symbols and automatic propagation of modifications from parent object to child object

• Integrated support for multi-monitor systems

Recognition of pointing gestures

Support of Multitouch gestures for an intuitive interaction with the HMI project

• Scroll

• Flick ↔

• Dual Touch: simultaneous touch of two different command objects

• Objects drag & drop on

• Win 32/64 runtime

Scalability

Premium HMI offers a unique development environment to realise the user interface of all ASEM HMI solutions based on ARM Cortex and x86 architectures with Windows CE and Windows 32/64 operating systems

• Premium HMI allows the company to keep just one software platform to meet all visualization needs, from the simplest projects to more demanding supervision applications, thus saving time in learning, updating and personnel training

Connectivity and communication

Premium HMI has a complete communication drivers library for the most used PLCs on the market

• Specific wizards allow the import and automatic configuration of project Variables (Tags) directly from the PLC project, reducing configuration time and errors

• Premium HMI 5 integrates OPC UA Client and OPC DA Client technology (the product meets the certification criteria established by the OPC Foundation)

• Automatic tag import from CODESYS Workbench for a better integration of control and visualization environments

• VBA interface for dynamic control of communication parameters (in runtime)

Premium HMI also provides:

• High performance and reactivity of controls to meet the most demanding requirements of machine manufacturers that need fast data updating and a prompt dispatch of commands to actuators

• Support for multi-protocol interfacing with data transfer function (gateway) between communication channels

• Real-Time I/O ODBC Link provides connectivity towards company’s information systems. Each variable (Tag) has the reading-writingconnectivity to an external relational DB. Therefore the Real-Time DB of the project can be shared automatically (partially or entirely) on a DB table, allowing sharing of plant’s real-time data with the company’s ERP

• Availability of normalisers for the application of nonlinear transformations to the variables

Networking

Premium HMI 5 has sophisticated Networking technology able to connect different HMI stations via Ethernet with multilevel Client/Server architecture

• The Client/Server architectures are supported by integrated functionalities that allow online distribution of both dynamic information and projects

• Local execution of Client projects works by loading the project from servers

• Efficiency and performance are guaranteed by the "eventdriven" architecture for data synchronisation

• The server stations can be based indifferently on Windows CE or Windows 32/64

Openness and flexibility

Premium HMI is based on XML, ODBC, OPC, VBA, TCP/ IP and SQL standard technologies, integrated in the platform to guarantee easy access and data transparency

• Projects are stored in XML format, which can be edited even with external Editors

• Support of data sharing on shared memory

• Data storage management on relational database (MS SQL Server, Oracle, MySQL, MS Access, SQL, etc.)

• Native support of Microsoft Visual Source Safe, a tool allowing online management of projects which is used by development teams to guarantee security, multiusers, changes traceability, maintenance and recovery of project versions

Data logger, Trends and Data Analysis - Traceability of data and historical archives

The Data Logger is the main tool for process data recording.

In addition Premium HMI offers sophisticated tools such as Trends and Data Analysis objects to analyse and represent logged data

• Simple configuration of process data sampling options

• Data can be recorded by frequency (time), or at event or variation (with dead band)

• Data storage on Database and text file both in local and remote

• Trends are graphic objects representing curves regarding the tendency of process data

Trends can be either dynamic or historical and have multiple features to represent graphically value. They are directly linked to Data Loggers and allow you to represent data by time period or other types of filters, zooms, pen selection, logarithmic scale, average value, compressed representation of the whole graph on one page, etc.

• Data Analysis objects are more sophisticated than Trends and allow you to analyse and graphically represent logged data recorded by Data Loggers

Data Analysis objects execute quick analyses at pre-set periods, comparisons and overlapping of curves (analyses with sample curves or comparative analyses of different periods, difference between values of two different graphs, etc.)

Premium HMI provides also:

• Traceability of variable modifications, with storage of the old and new value and modification’s author

• Visualization of events history, both from local database and network server (view of server HMI alarms from Client interface)

• Data archive export in .CSV format

Recipe manager

Production recipes allow you to manage archives containing operating parameters of the production process of different products

• Production recipes are managed by objects with the same recording techniques as Data Loggers, both on Database and on text files

• Selecting the desired product, it is possible to activate parameter values relating to the process variables

• Possibility to have multiple recipe structures inserted inside one another to design complex modular machines

• Simplified configuration with project structures for recipe use. The object technology allows you to create a "recipe" object and, once the related variable has been assigned to it, a specific "wizard" automatically generates the recipe management window, with a fully customisable user interface (fonts, colours, etc.)

• As an alternative, a simple grid viewer object allows you to manage recipe data traditionally

• Recipe data can be exported and imported in.CSV format

Alarm manager

Premium HMI provides maximum reliability in events management, guaranteeing continuous and immediate system/ machine monitoring, improving its efficiency and minimising production downtime

• Alarms are managed according to ISA S-18 standards, but they are entirely customizable with high-configurable objects and templates-oriented programming (threshold alarms, digital alarms, warning messages without recognition cycle, etc.)

• Simple definition and configuration of repetitive alarms using templates

• Fixed or variable triggering thresholds determine activation of the alarm, managing the four standard operating statuses (ON, OFF, ACK and RST) and the consequent representation of active alarms in visualization objects, managed by Windows or Banners with several filters (by time, area, priority, period, etc.) and the possibility to dynamically combine help and wizards on external files (CHM, HTML, PDF)

• Library tools for the organic visualization of active alarms, alarms awaiting acknowledgement and the alarm log with the possibility to apply visualization filters for a simple search and analysis

• The Alarms Window and the Historic Log Window are the tools to visualize active or stored alarms and can be inserted and configured as objects in any screen

• Premium HMI introduces the possibility to select an active alarm and directly view its history in the alarm window

• The Alarm Log automatically records all the events (Alarms, Driver Events or System Events) on the relational database (even on Windows CE) or on text files

• Alarm Dispatcher to promptly send alarms or messages via SMS or E-mail; the notification is sent to the specific User or Group of Users and can be customised depending on timetables, calendars, work shifts, etc. SMS notification dispatcher based on SMPP protocol (dispatches SMSs via Internet without modem)

Scheduler and Event generator

Scheduler objects offer maximum configurability of commands executed on a temporal base in Runtime

• Premium HMI schedulers manage time-based programming of any control, with flexibly configurable timetables. The operator has full freedom to establish commands, events and periods

• The schedulers are supported also by Windows CE and Web Client

• "Event Objects" define lists of commands that can be flexibly configured "Event Objects" drastically reduce the need to use code, executing command actions associated to events generated by variables (Tags) or by actions bound to command objects (e.g. buttons, menus, etc.)

Security and standards

Premium HMI applications guarantee maximum level of safety and reliability in compliance with CFR21 part 11 standards

• Users and Passwords management has been expressly designed to guarantee simple and integrated implementation of projects conforming with the severe CFR21 part 11 standards of the American FDA (Food & Drug Administration)

• Maximum protection of data and system access by managing criteria according to 1024 User levels and 16 access areas

• Data recording (Data Loggers, Events or any other data) is performed both on safe relational database (e.g. Ms SQL Server or Oracle) and in proprietary format (.DAT or .XML formatted text) encrypted with 128 bit encryption, to obtain recorded data that are visible only to Premium HMI controlled access features

• Additional tools: electronic signature, control of tampering attempts, password expiration, automatic log-off and management of Audit Trails

• Support to the management of RFID modules

Scripting and integrated languages

Premium HMI integrates a powerful VBA Engine (both for Windows CE an for Windows 32/64), able to execute codes that are perfectly compatible with the VBA standard (Visual Basic for Application) and to use a wide range of API for the most different project features

• Scripts can be executed as normal routines or "encapsulated" in objects in response to events (graphic objects, alarm objects, data loggers etc.)

• Scripts support multithreading, the simultaneous execution of different scripts.

Premium HMI provides also:

• VB.Net syntax support and management of software components based on .Net technology (only on Windows 32/64)

• VBA expression generator to edit logic expressions directly on objects instead of assigning variables

• Support of sequential combinational language, typical of PLCs (Instructions List IL or AWL)

• Openness to integration of ActiveX, OCX, DLL software components

Multi-language support

Each Premium HMI project can contain all the text strings in a virtually unlimited number of languages and with any Unicode character, even with UTF-16 code for Asiatic and Arab characters

• Editing texts in different languages is facilitated by import/export tools

Texts are managed in the project string table, compatible with Copy/Paste operations of Editors like Microsoft Excel

• Any language can be changed and activated both in Editor and in Runtime modes

• A specific language can be activated when a specific Audit Trail user logs on

• The font size is automatically adjusted dependig on the language selected, optimizing the filling of the text boxes

Print reports

Premium HMI integrates a simple and flexible tool in the development environment to make multilanguage printing reports

• Possibility to fully customize printing pages with Copy/Paste operations of variables and objects from the project pages (even graphs like trends, plotters, etc.)

Premium HMI provides also:

• Printing of objects with values which change dynamically over time

• Printing of variables present in the Data Logger, both on the Database and in .CSV format

• Printing on file, printer and creation of PDF files

Debugging tools

Premium HMI has an integrated simulator to execute debugging without transferring the project in the target. The simulator allows communication with the protocols configured in the project

• Powerful online debugger to analyse and simulate the project, both locally and remotely (even during execution)

• Possibility of full project recovery from the target hardware device for a safe and protected modification of the password (with retransmission of the modified project to the target device)

• In case of multi-language projects, control/verification of non-translated text strings

Premium HMI provides also:

• Verification and reporting of variables not used in the project (Cross Reference )

• "Refactoring" tools for the automatic design error correction

Support for Web Client remote control

Premium HMI offers the best Web Client technology with remote access independent from local operation

• Remote control of projects with "Premium HMI Mobile", free App for iOS and Android devices (needs Premium HMI 3.0.1102 or later releases)

• The Web Client with JAVAbased architecture allows the server and projects to be accessed via Internet browser from any platform and operating system

Features and Runtime versions

Supported protocols

(1) Requires CODESYS Gateway running on controller side

(2) Requires PLC communication support program supplied by ASEM

(3) PVI communication libraries supplied by B&R are mandatory

(4) ADS communication libraries supplied by Beckhoff are mandatory

(5) "Ethernet-MPI Gateway" function, local or remote using UBIQUITY,

supported ONLY with PHMI5

(6) Only OT600/HMI600/Smartbox

(7) Supports the variable import from TIA Portal and communication

S7-1200 / S7-1500 controllers via absolute addressing (no symbolic)

(8) Supports the variable import from TIA Portal and communication

S7-1200 / S7-1500 controllers via symbolic addressing

FAQ

Premium HMI is “transparent” to the concept of display orientation. The only information required by Premium is the page size.

To make an application in portrait mode you just need to rotate the display and provide to the Premium HMI a new page size with a width size less than the page height size.

The display rotation is an operating system feature and it is supported by all the Win32 systems and by the Windows CE devices starting from version 7.

In case, for example, of HMI30 the display rotation can be done using the “Freescale display driver” utility available in the Control Panel, accessible from the “Start” menu.

The utility allows changing the display orientation freely as shown in the picture.

The license type information is returned by the Output Windows as a system message during startup.

An example is shown in the picture.

The visualization of the output window is optional and needs to be activated from the project properties as shown in the picture.

All Premium HMI projects require setting the License type as shown in the picture.

In case the license type provided in the project does not match the Runtime one, the output window will display an error message.

When Premium HMI is started up on WinCE systems it is possible to view both the version and the type of license installed.

In order to save memory, the operator panels are featuring a limited set of supported fonts/characters. The WinCE image includes the following fonts:

- times.ttf

- tahoma.ttf

- symbol.ttf

- segoeui.ttf

- cour.ttf

- wingding.ttf

In case the Premium HMI project requires additional fonts, the corresponding “.ttf” file has to be manually copied to the following folder:

\MMCMemory\copytowindows

If the folder is not present, then it must be created.

All the files contained in this folder will be automatically copied to \Windows during the startup phase and then will be accessible to any applications, including of course Premium HMI Runtime.

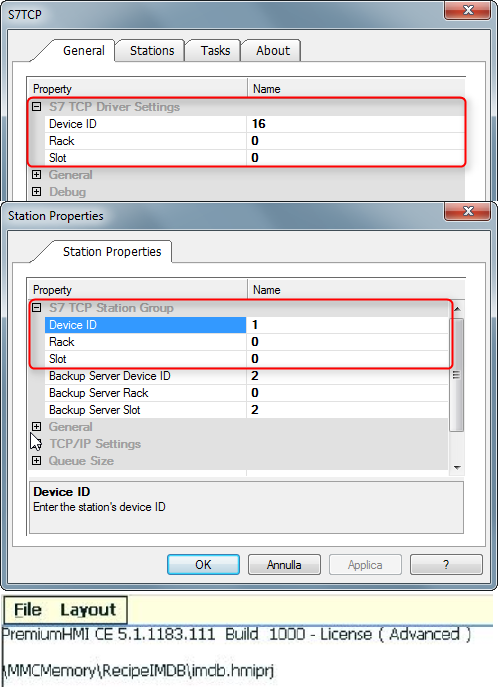

By factory default the Logo! controllers expect the TSAP parameter for the HMI (client) set to 02.00 (hex) while the TSAP parameter for the controller (server) set to 02.00 (hex).

The Premium HMI communication driver must be properly configured.

The TSAP parameter for the HMI (client) can be set from the “General settings” tab of the communication protocol settings dialog as shown in the picture at the top.

The TSAP parameter to be used for the connection with the controller (server) can be set from the Station properties. When using the PLC factory settings the parameter has to be set according to the picture at the bottom.

Note: set the "S7-200" parameter to "true"

Why the alignment between rectangle objects with thick borders changes between Premium HMI Studio simulation and HMI30/25 Runtime?

There is a difference in the way the Win32/64 and WinCE operating systems paint the border for objects like rectangles but in general also for polygons.

For Win32/64 systems the border is always painted inside the object. For WinCE systems the border is painted for half inside and for half outside.

This means that the final size of a rectangle painted on WinCE system can be bigger than the one specified in the “Position” properties by a value that is half of the border size.

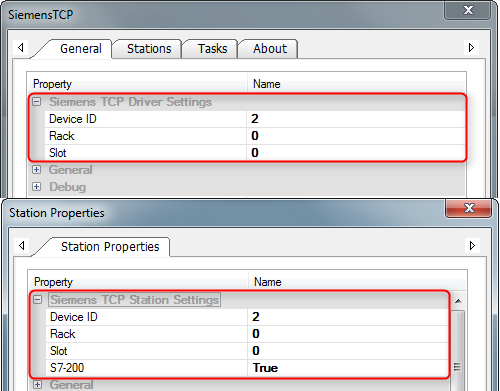

Oriental languages are managed by ASEM System Manager.

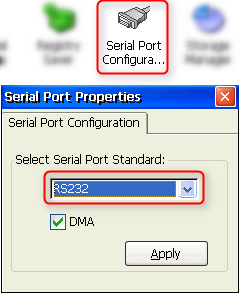

The panels are equipped with a multi-standard serial port. The serial port mode must be selected from the HMI Control Panel. Close on the HMI the Premium Runtime and access to the Control Panel from “Start\Settings\Control Panel”. Start the utility “Serial Port Configuration” and select the desired configuration based on the protocol and the communication type.

The possible choices are the following:

- RS-232

- RS-485 (2 wires)

- RS-422 (4 wires)

- MPI

Serial port settings do not require registry save.

Note: the S7-MPI COMx communication driver supports the automatic serial port mode settings and it is the only one that does not require a manual port setup.

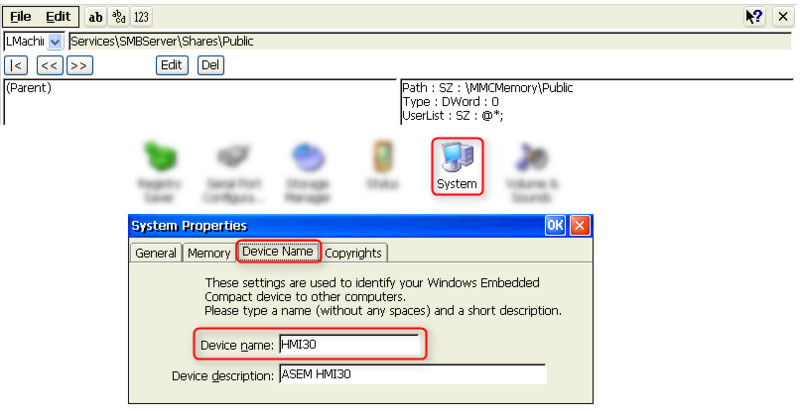

The HMI30/25 systems support directly the sharing of a specific folder to be created in “\MMCMemory”.

If you create the folder named “Temp” under “\MMCMemoru” this folder will be automatically shared over the network. By factory default the authentication is disabled and the shared is accessible to any user.

From the registry editor, you can change the name to be used for the shared folder or add a new one.

On the panel close the Premium HMI Runtime and start the registry editor by typing “regedit” in the “Run” window accessible from “Start\Run”.

Locate then the key HKEY_LOCAL_MACHINE\Services\SMBServer\Shares

The keys shown correspond to the names to be used for the shares.

By factory settings, there is one single key named “Temp”.

To create a second share select “Edit\New Key” and use, as the key name, the name you want to use for the new share. For instance, let’s use the name “Public”. Leave the “Class of the key” field empty.

Within the newly created “Public” key assign the following values:

Path: SZ : \MMCMemory\Public

Type: DWord : 0

UserList: SZ : @*

After the registry editing has been completed, it requires to be manually saved by using the “Registry saver” utility available from the Control Panel accessible from “Start\Control Panel”.

In the “\MMCMemoru” create now the folder “Public”.

Restart then the system.

To access the shared folders from an external PC connected over the same panel sub-network, use Resource Explorer and type in the address bar:

\\[IP_HMI]\[shared_folder_name]

where [IP_HMI] is the IP address assigned to the HMI panel and [shared_folder_name] is the name of the shared directory.

As an alternative to the panel IP address, it is possible to use the device name. The device name can be set from the following windows accessible from the “System” icon in the Control Panel.

The changes to the device name do NOT require to be manually saved in the registry.

The panels are based on ARM processors and they use the Windows Embedded Compact 7 operating system, very often referred to as “WinCE”. They support two ways of storing historical data. The first uses a database called “IMDB” (In-Memory Database) the second one uses “SQL CE” (relational database) supported by ADOCE which is fundamental in WinCE systems as they do not support ODBC. Refer to the Premium HMI Studio online help for any additional detail about the databases and the differences between them.

Recipes and Dataloggers can be freely configured to store data on IMDB or SQL CE databases. Depending on the selected database the maximum number of configurable columns for a recipe or a data logger is subject to different restrictions:

IMDB: max 90 columns (127 for Win32/64 systems)

SQL CE: max 1024 columns (1024 per Access on Win32/64)

In case the application requires a higher number of columns for a recipe (for instance) you will need to split the columns in between several recipes and implement synchronized handling. Synchronized handling can be done using the same Index for all the recipes and providing commands (Activate, Read, Save..) using the tags.

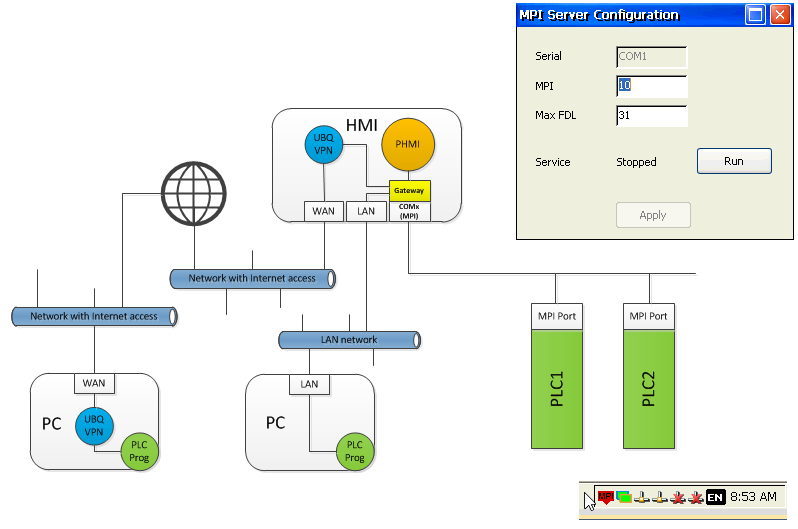

The Ethernet-MPI service allows using the Step 7 programming software through the Ethernet interface of the PC where it is installed to program/debug an MPI compatible controller which is connected to the HMI25 and HMI30 anel serial port through the MPI bus.

The principle of operation is shown in the picture.

The complete description of the feature can be found in the “S7-MPI COMx” communication protocol online help, which is distributed with Premium HMI Studio version 4 or above. For reference, you can get the CHM format of the online help from the following link.

The gateway service is automatically installed by the Premium HMI 4 (or above) Runtime installer. This FAQ describes how to manually install the service for HMI30/25 systems with the previous version of Premium HMI Runtime.

For the manual installation proceed as follows.

- Download the installer from the following link; extract the file and copy it to the HMI disk.

- If running, close the Premium HMI Runtime on the panel. From “My Device” open the “Windows” folder” and launch the batch file “MakeNANDWritale”; this will remove the read-only protection normally present on the “NADFlash” disk.

- Launch the installer previously copied on the panel (MPIServerSetupWinCE_ARMV4I.exe). At the end of the installation, you will find a new folder under “NANDFlash” called “MPIServer”.

- Start the service launching (double click) the file “MPIServer.exe”. In the following window insert the MPI node of the panel and the maximum node number (Max FDL) present in the MPI network.

The service is activated when you click on the “Run” button.

Once started, you will see the icon in the notification area. The icon is red when there is no connection and it turns green when there is at least one connect client.

Note: the service is NOT compatible with the “S7-MPI COMx” version of the driver distributed with Premium HMI 3 and in any case prior to version 12.1.0.0. The use of the service requires closing Premium HMI Runtime before activating it. Premium HMI Runtime can be re-started after you have terminated the service by clicking on the ”Stop” button (The “Run” button turns to “Stop” once the service is running)

The Premium HMI operator panels are based on ARM processors and they use the Windows Embedded Compact 7 operating system, very often referred to as “WinCE”.

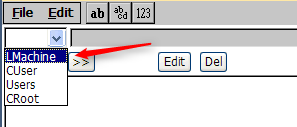

The version ID of the operating system can be retrieved from the Windows registry. The registry can be displayed using the "regedit" application. To start "regedit", click on the "Start" button, then click "Run" and type "regedit", then click OK.

Select then "LMachine" from the list box menu as shown in the picture.

Double click on the "ASEM" key. The version ID corresponds to the last two digits of the "Version" key, after the dot. The new version will be then identified by 8922005A.07.

System requirements

Personal area

Login to your personal area to download your restricted contents. If you don’t have am ASEM account yet, register here.

- EULA_PremiumHMI_DEU.pdf (162.88 KB)

- EULA_PremiumHMI_ENG.pdf (179.69 KB)

- EULA_PremiumHMI_ITA.pdf (201.19 KB)