Discover new products

Company

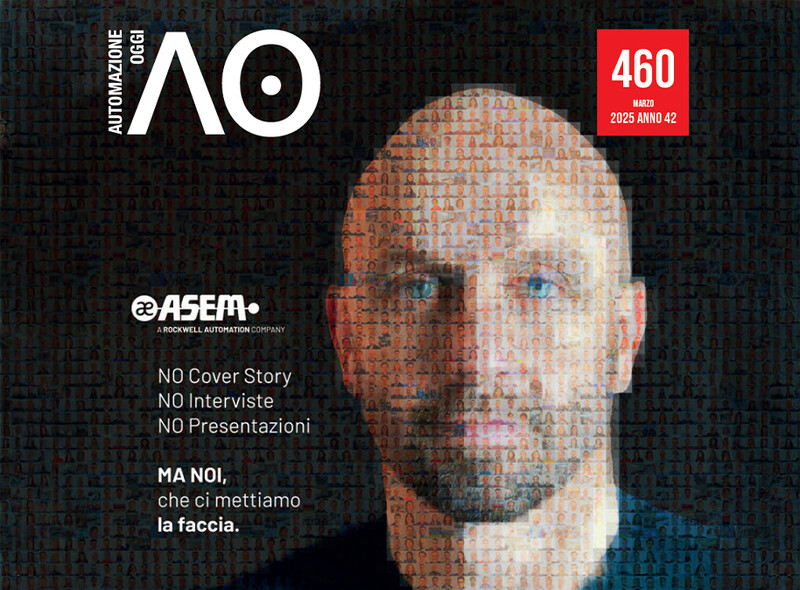

ASEM - A ROCKWELL AUTOMATION COMPANY

CONTINUITY IN TECHNOLOGICAL IDENTITY, FLEXIBILITY AND BUSINESS APPROACH IN THE GLOBAL CONTEXT

Continue

44

yearsof activity

250

employees9600

mqheadquarters

News & Events